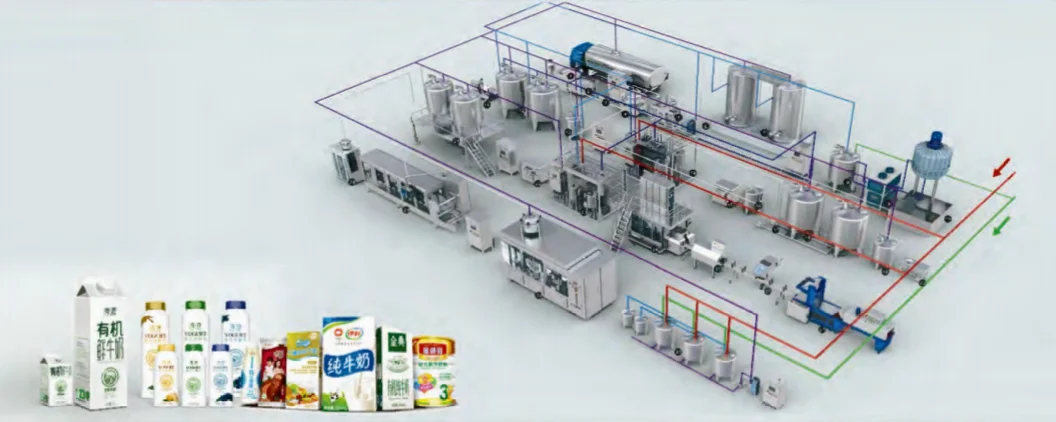

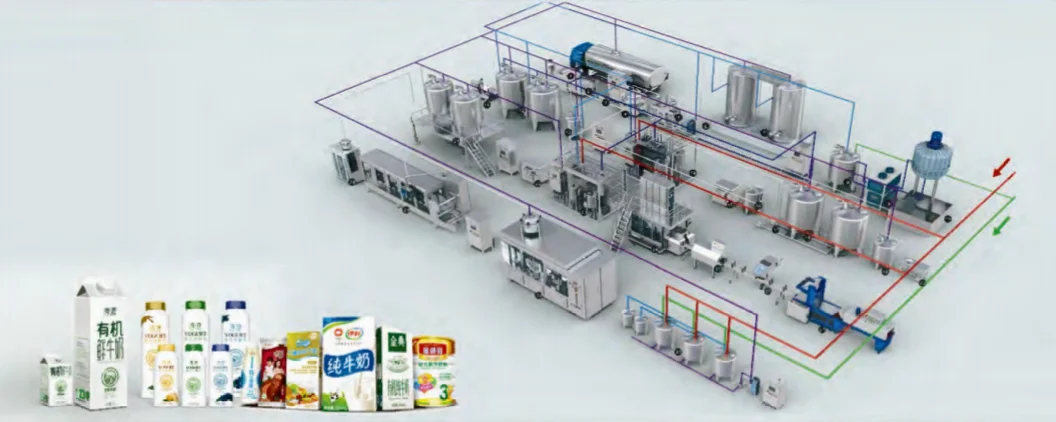

Small Yogurt Production Line

Basic process

The standard production process of pasteurized milk: raw milk → storage tank → filtration → preheating → homogenization → sterilization → pre-cooling → fermentation → filling → CIP cleaning.

Simplified production process of pasteurized milk: raw milk → storage → sterilization → cooling → fermentation → filling

Corollary equipment

The standard process equipment for pasteurized milk is: raw milk → pump → storage tank → pump → duplex filter→ pump → preheating tank → pump → homogenizer → pump → stirring sterilization tank → pump → pre-cooling tank → pump → Fermentation tank → pump → filling machine → CIP cleaning system

Process introduction

Store the whole milk in the raw milk tank, and then pump the raw milk into the preheating tank through a special stainless steel milk pump and a duplex filter for preheating. Generally, the preheating temperature will be around 45°C.

After preheating , the raw milk is poured into the homogenizing tank for homogenization, and corresponding auxiliary materials are added to make the raw milk smoother after homogenization.

After homogenization ,start the centrifugal milk pump , and the raw milk is pumped into the pasteurization tank for sterilization and stirring.

When sterilization is required, turn on the centrifugal milk pump connecting the original milk tank and the pasteurization tank, and pasteurize it with 350# heat transfer oil or hot water/steam. According to different heat sources and output, the sterilization time is generally 0.5 to 1.5 hours , and the pasteurization temperature is 85℃.

After sterilization , the fresh milk is pumped into the pre-cooling tank through the milk pump. The pre-cooling tank uses cold water for pre-cooling, and then pumps it into the fermentation tank, adding corresponding strains and starters, and starter for yogurt fermentation.

CIP system does not decompose production equipment, but can also use simple operation methods to clean the system. safely and automatically It has been introduced into almost all food, beverage and pharmaceutical factories. CIP system can not only clean the machine, but also control microorganisms.

The CIP cleaning system is composed of three storage tanks with weak acid water, weak alkali water, and clean water, as well as pumps, pipes, valves, etc. The equipment is cleaned by the circulation of three liquids, so that the equipment is clean and has no sanitary dead corners. In principle, it is recommended that customers use the CIP cleaning system, but the cost of the CIP cleaning system is higher. If the output is low, the customer can also choose manual cleaning.

The company has a group of professional technology research and development teams and advanced processing equipment, and a number of invention patents. The company produces a wide variety of packing machinery, the main products are: vertical form fill seal (VFFS) machine, stick pack machine, powder packing machine, liquid packing machine and multihead weigher series, which are widely used in food, chemical, beverage, agricultural products, toys and Packing in industrial products and other industries, the products are exported to all over the world, and have obtained professional marketing agents in many countries and regions.The products and services have been unanimously recognized and praised by customers.